|

|

|

Low-cost 6-axis force-torque sensors are needed in the fields of robotics, human interface and healthcare applications. Large-size, which means non-MEMS, 6-axis force-torque sensors with more than 17 mm in diameter and 14 mm in height using strain gauges or capacitance sensors are commercially available. However, even the ATI Nano17, the smallest one in this category, is unsuitable for the preceding fields because of its size, especially its height.

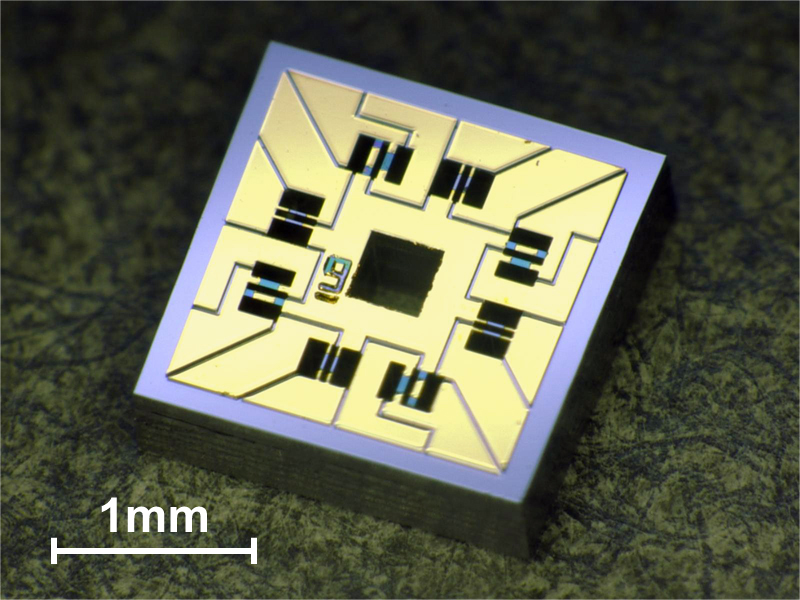

In this research, we proposed a 6-axis force-torque sensor chip composed of 16 piezoresistive beams which will be embedded in the designed resin with proper size and hardness such as silicone rubber or epoxy resin for each practical purpose. The sensor chip’s area, 2mm square in size, is one-third of that of the minimum 6-axis sensor chip ever reported. It will enhance the mounting density of sensor array and also reduce the cost in case of volume production. These sensor chips were fabricated by MNOIC (MicroNano Open Innovation Center), 8-inch MEMS foundry in Japan, and their characteristic variations are enough small to make practical use of them. It was confirmed that the fabricated sensor with epoxy resin can detect 3-axis forces and 3-axis moments by the calibration and characteristic evaluation of the fabricated sensor.

References :

1.Akihito Nakai, Yasuhiko Morishima, Kiyoshi Matsumoto and Isao Shimoyama, “6-axis force –torque sensor chip composed of 16 piezoresistive beams,”; The 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2015), Estoril, Portugal, pp. 730-733, January 18-22, 2015. [Procedding]

|